- Next-generation pharmaceutical glass tubing reduces carbon emissions by 50% thanks to innovative electric melting technology and 100% green electricity, helping pharmaceutical companies and packaging manufacturers to significantly reduce the overall emissions of their products

- Construction of electric glass melting tank started in Mitterteich

- Product carbon footprint of FIOLAX® Pro OCF as the first SCHOTT product calculated according to the highest industry standards and externally certified

The international technology group SCHOTT has set itself the goal of sustainably transforming its energy-intensive specialty glass production. At the same time, the company is continuously working on advancing its materials, now opening the next chapter with its FIOLAX® Pro OCF pharmaceutical glass tubing. A technically complex change in production is intended to reduce the product carbon footprint and thus the carbon emissions[1] of the pharmaceutical glass by 50%. The abbreviation “OCF” in the product name stands for “Optimized Carbon Footprint.” The company is achieving this reduction in emissions by using innovative, electrified melting technology in combination with 100% green electricity, for which the groundbreaking ceremony took place today in Mitterteich, Germany. SCHOTT is thus taking a decisive step toward technological change in the specialty glass industry while supporting its customers and the pharmaceutical industry in achieving their own environmental goals.

The international technology group SCHOTT has set itself the goal of sustainably transforming its energy-intensive specialty glass production. At the same time, the company is continuously working on advancing its materials, now opening the next chapter with its FIOLAX® Pro OCF pharmaceutical glass tubing. A technically complex change in production is intended to reduce the product carbon footprint and thus the carbon emissions[1] of the pharmaceutical glass by 50%. The abbreviation “OCF” in the product name stands for “Optimized Carbon Footprint.” The company is achieving this reduction in emissions by using innovative, electrified melting technology in combination with 100% green electricity, for which the groundbreaking ceremony took place today in Mitterteich, Germany. SCHOTT is thus taking a decisive step toward technological change in the specialty glass industry while supporting its customers and the pharmaceutical industry in achieving their own environmental goals.

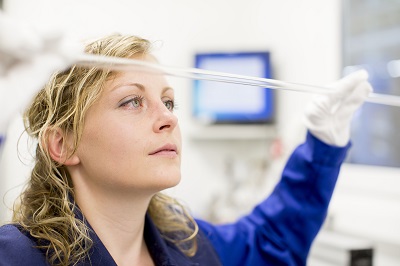

SCHOTT, a pioneer in the field of specialty glass, is committed to continuously optimizing its materials and making them more sustainable. In the pharmaceutical industry, the company’s borosilicate glass – known under the brand name FIOLAX® – has been the gold standard for over a century to safely store or administer vital medications. The pharmaceutical glass tubing is used to manufacture high-quality syringes, cartridges, vials, and ampoules.

With FIOLAX® Pro, the glass of the future, and its OCF product line, the company is expanding its existing product portfolio and reducing emissions from pharmaceutical glass. In doing so, SCHOTT is also helping its customers in the pharmaceutical industry to reduce the overall emissions of their products.

The glass tubing has the same properties as FIOLAX® Pro but significantly reduced carbon emissions due to its new manufacturing process. The switch to an innovative electric melting tank that uses 100% green electricity, and a minimal amount of natural gas has made it possible to reduce GHG emissions. Looking at the melting process alone, emissions can be reduced by 80%. If the raw material extraction and post-processing of the glass are also considered, the new product line causes 50% less carbon emissions than conventional borosilicate glass production.[2]

Externally certified Product Carbon Footprint according to the highest industry standards

Transparency and comparability are crucial in the field of sustainability. That is why SCHOTT has based its calculation of the Product Carbon Footprint (PCF) for FIOLAX® Pro OCF on the highest industry standards currently available.

The calculation is based on a specially developed SCHOTT PCF Guideline that can be applied to all of the company’s products. It follows the globally recognized ISO 14067 standard as the basis for PCF development, the Greenhouse Gas (GHG) Protocol for accounting greenhouse gas emissions, and the PCF guidelines of TfS (“Together for Sustainability”), a comprehensive sustainability initiative of the chemical industry. The accredited, independent testing institute GUTCert led the external certification.

PCF transparency pays off for SCHOTT’s customers, as it enables them to calculate the PCF data for their own products (containers or medications) much more accurately and transparently based on real data for pharmaceutical tubes.

“We are very proud to have received validation from GUTcert. As a pioneer in the manufacturing of specialty glass using electric melting technology, we offer our customers not only an outstanding product, but now also a high-quality, externally verified PCF calculation,” says Marius Amschler, sustainability expert at the Tubing business unit. “This gives the pharmaceutical industry additional opportunities to identify and implement measures to reduce greenhouse gas emissions.”

Innovative melting tank technology sets new standards

Over the past two years, SCHOTT experts have been laying the foundation for a new melting technology through various development projects. This research work is now being transferred to large-scale production with a new, innovative melting tank in which natural gas-based regenerative technology is being replaced by electric melting technology. The pilot tank, which the company will build at its site in Mitterteich, is a pioneering development for the entire specialty glass industry.

“The transformation of our industry toward decarbonization and significantly lower-carbon processes begins with concrete projects. This pilot tank is an example that sends a strong signal,” explained SCHOTT CEO Dr. Torsten Derr. “We are investing specifically in technology that avoids emissions while also strengthening the competitiveness of our site.”

With today’s start of construction, pharmaceutical glass tubing production is scheduled to begin in early 2027. Around 40 million euros have been invested in this project, financed by SCHOTT and subsidies from the German Federal Ministry for Economic Affairs and Climate Action. Almost 15 million euros were financed by the “Decarbonization of Industry” program managed by the Competence Centre on Climate Change Mitigation in Energy-Intensive Industries (KEI), which also include funds from the EU’s “NextGenerationEU”. KEI Deputy Director Dr. Ricarda Tänzer-von Daake personally congratulated the Group’s management on this important milestone towards climate neutrality in the glass industry. The KEI team of experts will continue to support the implementation of “PROSPECT Pilot.”

“With our innovative tank concept, we are setting a new standard by offering CO2e-reduced solutions for all primary packaging formats, from syringes and cartridges to pharmaceutical vials and ampoules, based on the new FIOLAX® Pro OCF product line,” said Dr. Patrick Markschläger, Executive Vice President of SCHOTT’s Tubing business unit. “This is a huge step for us in decarbonizing our production. We are offering our customers the opportunity to test and validate FIOLAX® Pro now so that they are prepared for FIOLAX® Pro OCF in 2027.”

“With our innovative tank concept, we are setting a new standard by offering CO2e-reduced solutions for all primary packaging formats, from syringes and cartridges to pharmaceutical vials and ampoules, based on the new FIOLAX® Pro OCF product line,” said Dr. Patrick Markschläger, Executive Vice President of SCHOTT’s Tubing business unit. “This is a huge step for us in decarbonizing our production. We are offering our customers the opportunity to test and validate FIOLAX® Pro now so that they are prepared for FIOLAX® Pro OCF in 2027.”

1 Emissions references refer to CO2 equivalents (CO2e).

2 Calculation of greenhouse gas emissions according to Cradle-to-Gate (“from cradle to factory gate”) per kg of saleable tubular glass; compared to the market average for borosilicate glass tubing [average value according to ecoinvent 3.10; production of glass tubing, borosilicate // DE].