The pharmaceutical industry stands at the confluence of innovation, regulation, and global interconnectedness. Its supply chain, historically concentrated on medicines and health product distribution, has now transformed into a sophisticated system powered by technology advancements, the growing need for transparency, and the need for strong, resilient logistics networks. With healthcare becoming increasingly personalized and precision medicine, the supply chain will have to keep pace with these evolving requirements while ensuring the highest levels of safety, efficacy, and regulatory compliance.

The past few years have been characterized by swift digitalization in the industry, which has involved the use of sophisticated analytics, automation, and real-time monitoring. These technological changes are not only making a better efficiency but also strengthening security and transparency, particularly in dealing with temperature-sensitive biologics, vaccines, and other essential healthcare products. The pharma supply chains of the future will be influenced by upcoming trends that are centered on digitisation, sustainability, and risk mitigation, which will ensure an agile and resilient system that can withstand global disruptions and changing healthcare requirements.

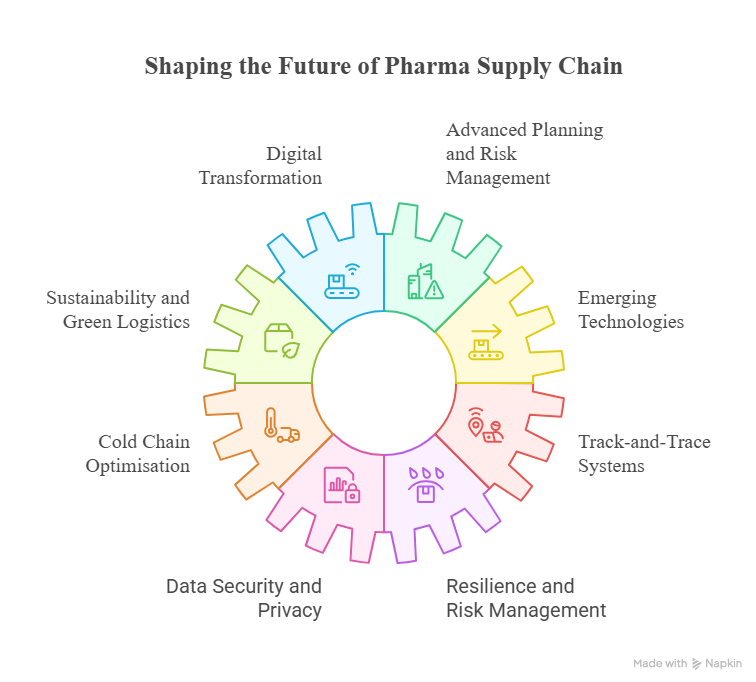

Trends Shaping Future of Pharma Supply Chain

-

Digital Transformation

At the heart of the recent trends is an accelerated digital transformation. The blending of smart data analytics, artificial intelligence, and Internet of Things devices has transformed conventional logistics models. With real-time location tracking and predictive analytics, supply chain managers can now monitor shipments at every point of the journey—from manufacturing to delivery—with unparalleled visibility.

Digitalisation improves the accuracy of demand forecasting so that businesses can better predict shortages or surpluses. This is especially important in today’s environment, where supply chain disruptions, whether due to geopolitical tensions, pandemics, or climate events, can very much affect the availability of critical drugs. Through the use of machine learning algorithms, businesses can model different scenarios, reduce inventory levels, and optimize distribution routes, substantially cutting down on waste and costs.

-

Advanced Planning and Risk Management

The COVID-19 pandemic laid bare the vulnerability of global supply chains, and as a result, there has been a strategic transition to positioning for resilience. Companies have responded by embracing multi-source purchasing models, regional production centers, and responsive logistics designs that can quickly respond to disruptions.

Artificial intelligence and machine learning are working their magic to support supply chain resilience. Predictive analytics can spot potential bottlenecks and weak points before they happen, allowing proactive measures to be taken to mitigate these. For example, AI-based demand sensing models process patterns in multiple variables—such as epidemiological trends, seasonality, and policy changes—to predict future demand highly accurately.

-

The Shift Towards Sustainability and Green Logistics

Sustainability is now a key concern in pharma supply chain and logistics management. The environmental impact of the industry—high energy use, waste, and greenhouse gases—is being scrutinized by regulators, investors, and consumers.

The businesses are increasingly embracing environmentally friendly logistics methods, such as optimizing routes to minimize fuel use, the switch to hybrid or electric cars, and biodegradable packages. Furthermore, digital monitoring and analytics reduce unnecessary inventory and wastage due to expired drugs.

Additionally, sustainable processes are also carried over into manufacturing and packaging. Solutions like biodegradable plastic, reusable containers, and environmentally friendly materials used for transit packaging are becoming popular. The aim is to have a circular supply chain that not only makes delivery of medicines efficient but also reduces environmental footprint.

- Emerging Technologies

The future of pharma supply chain and logistics will be influenced by new technologies that hold the promise of more automation, more intelligence, and more sustainability. Autonomous drones and cars are already being piloted for last-mile delivery, particularly where the terrain is difficult or infrastructure limited. Autonomous solutions have the potential to cut delivery times, reduce costs, and enhance access to life-saving medicines.

Artificial intelligence will keep getting better, allowing more accurate demand forecasting, real-time decision-making, and dynamic routing. Visual inspection systems using AI are also being utilized to authenticate the integrity of packaging and cold chain conditions in transit.

Digital twins—computer-based copies of physical assets or supply chain networks—are increasingly popular as a means of simulating logistics operations, detecting potential points of failure, and optimizing overall performance. This virtual modeling is central to creating resilient, flexible supply chains that can handle unexpected disruptions.

Additionally, the integration of blockchain technology will become more profound, offering a transparent, decentralized, and tamper-evident record of all transactions and managing events for pharmaceuticals. Such a level of traceability and transparency will be critical for compliance, recalls, and authenticity of the product.

-

Cold Chain Optimisation and Temperature-Controlled Logistics

Temperature-sensitive drug management continues to be one of the most challenging and complicated aspects of the pharmaceutical supply chain. With the growing focus on biologics, gene therapies, and personalised medicine, there has been tremendous innovation in ensuring product integrity from manufacturer to patient delivery.

Specialty drugs and biologics are sensitive products and generally require stringent temperature management to hold their effectiveness. These products are fragile, expensive, and should be managed as little as possible to reduce degradation. Recent advancements in packaging involve highly engineered packaging such as phase-change material insulated shippers that hold a very accurate temperature range across a protracted time horizon. Some of the packaging used includes a built-in data logger that continuously monitors and records the temperature before, during, and after transport to figure out compliance and provide an instant means of better response to any deviations.

Digital platforms that have touched the three constituents of manufacturers, logistics providers and healthcare providers also include the required data interchange and decision-making real-time visibility. Networked digital systems give way to proactive measures to eliminate waste or expired and costly product losses.

Cryogenic logistics has emerged as a required service for the storage and transport of ultra-cold biologics, vaccines and cell therapies. Some innovation exists in the form of a new class of cryogenic containers, equipped with IoT (Internet of Things) sensors that track temperature, orientation, and environmental variables while in transport. These cryogenic containers are all too often a sophisticated engineered product with active cooling modes that can quickly react to changes in the outside temperature, controlling the time and conditions of the cryogenic environment inside as products must remain under strict cryogenic parameters.

-

Track-and-Trace Systems

Real time tracking technologies such as GPS combined with IoT sensors provide real-time visibility on at-risk shipments. Automated alert solutions alert all stakeholders immediately if a temperature excursion or other event has occurred, allowing everyone to act quickly to address it. Automation also applies in the warehouse via robotic systems that allow the safe handling and warehouse storage of frequency-sensitive products to support the reduction of human error, and efficiencies within the process.

It is important to note that when artificial intelligence (AI) is combined with real-time data streamlines predictive analytics making it possible for logistics providers/recruiters to assess potential disruptions and dynamically optimize routes. These technologies facilitate the safe, timely delivery of drugs that require temperature monitoring.

Security of authenticity and counterfeit protection is one of the most important issues related to the logistics of pharmaceutical distribution anywhere in the world. Emerging regulations plus the evolving technologies are confirming strong track-and-trace solutions that ensure greater overall safety for the supply chain.

-

Data Security and Privacy

As reliance on digital solutions in pharmaceutical logistics continues to rise, it is also critical to establish appropriate standards for data security and privacy. It is important to note that health information is sensitive data and one must also consider supply chain data.

The EU’s GPDR (General Data Protection Regulation) has established high standards across the trade bloc, in terms of data protection, specifically transparency, consent, and logic to minimize data. Supply chain solution developers should regard encryption and other methods to protect sensitive and personal data such as patient preferences, shipment details, or personnel information.

Current trends involve active technology implementation that includes advanced cybersecurity controls such as multi-factor authentication, intrusion detection, continual security audits (not only to prevent breaches, but to protect intellectual property and to build trust with stakeholders.

In seeing the impact of digital systems, regulators are increasingly paying attention to compliance audits to verify adherence to data governance requirements. Automated audits can track data access, use and security controls during processing in near real-time and provide instantaneous compliance audits. In addition to being able to take corrective action in real-time, these systems also allow for compliance certifications that reduce regulatory risk and ensure continuous compliance in-line with international standards.

DTP models require agile, trustworthy cold chain logistics to reach patients’ doors directly. They call for real-time location tracking, dynamic routing, and automated dispatching to deliver medicines safely and on time. This model makes specialised therapies accessible to a larger pool of patients, especially for managing chronic disease and rare conditions, and requires a sophisticated degree of integration between e-commerce platforms and existing supply chains.

-

Resilience and Risk Management

Due to repeated disruptions ranging from global pandemics to military actions, pharmaceutical supply chain resilience has gained momentum as an important strategic priority. Reducing dependency on a sole source requires diversification of raw materials sources, production sites and transport routes. Companies are investing in local production centers and dual sourcing arrangements to ensure continuity of supply. Companies are developing contingency plans around multiple transport modalities, including air, sea, road and rail to address disruptions quickly and efficiently.

Institutions can leverage big data and artificial intelligence-based analytics for advanced risk analysis. Predictive modeling identifies vulnerabilities in the supply chain, for example, delays in procuring raw materials, or transportation bottlenecks. Such results can help decision-makers plan contingencies, manage inventories, and redirect shipments so patients can ultimately obtain them when they need to.

Conclusion

The pharma supply chain and logistics landscape is being radically changed, driven by technology innovations, complex regulatory requirements, and demand for sustainable practices. The sector is advancing into a new era of solutions – from cold chain upgrades and digitalization to predictive analytics and autonomous delivery – which enhances the delivery of safe, efficient, and resilient solutions.

As the sector moves towards a future of more transparent, agile, and sustainable supply chains, stakeholders will need to come together to integrate these innovations into their own business practices. This ongoing transformation offers not only the prospect of superior patient outcomes achieved through timely delivery of quality medicines, but also a more green, safe, and resilient healthcare ecosystem to support the demands of the 21st Century.