Pharma 5.0: Human-Centric Automation for a Smarter Industry

The pharmaceutical industry stands at the threshold of its fifth major evolutionary phase, a transformation that promises to fundamentally reshape how medicines are discovered, developed, manufactured, and delivered to patients worldwide. Pharma 5.0 represents far more than incremental technological advancement; it embodies a comprehensive reimagining of pharmaceutical operations that places human expertise and patient needs at the center while leveraging cutting-edge technologies including artificial intelligence, robotics, and advanced data analytics. As the global Pharma 5.0 market prepares for explosive growth with a projected compound annual growth rate of 24.6 percent through 2034, this paradigm shift addresses critical challenges facing the pharmaceutical industry including rising development costs, increasingly complex regulatory requirements, growing demand for personalized medicines, and persistent quality and compliance imperatives. The integration of advanced automation with human intelligence creates synergistic capabilities that neither humans nor machines could achieve independently, enabling pharmaceutical companies to operate with unprecedented efficiency, agility, and patient focus.

The evolution from Pharma 4.0 to Pharma 5.0 reflects a fundamental shift in philosophy regarding the relationship between technology and human workers. While Pharma 4.0 focused primarily on digitalization, connectivity, and data-driven decision-making to improve operational efficiency, Pharma 5.0 explicitly emphasizes human-machine collaboration where advanced technologies augment rather than replace human capabilities. This human-centric approach recognizes that pharmaceutical development and manufacturing involve complex judgment calls, creative problem-solving, and nuanced decision-making that benefit from combining human expertise with computational power and automation precision. The patient-centric dimension of Pharma 5.0 extends this philosophy beyond internal operations to encompass the entire value chain, prioritizing development of personalized medicines tailored to individual patient characteristics and integrating patient data throughout discovery, development, and treatment processes.

The Foundational Pillars of Pharma 5.0

Patient-centric care forms the philosophical cornerstone of Pharma 5.0, representing a decisive move away from the traditional one-size-fits-all approach to drug development and treatment. This paradigm prioritizes understanding individual patient characteristics including genetic profiles, environmental factors, lifestyle considerations, and personal preferences in designing therapeutic interventions. The integration of genomic data, real-world evidence from wearable devices and electronic health records, and patient-reported outcomes creates comprehensive portraits of individual patients that enable truly personalized medicine. Pharmaceutical companies embracing Pharma 5.0 principles design clinical trials that identify patient subpopulations most likely to benefit from specific therapies, develop companion diagnostics that guide treatment selection, and create flexible manufacturing capabilities that can produce customized formulations or dosing regimens tailored to individual needs.

Human-AI collaboration represents the technological heart of Pharma 5.0, creating symbiotic relationships where artificial intelligence enhances human capabilities while humans provide creativity, contextual understanding, and ethical judgment that AI systems lack. In drug discovery, AI algorithms can rapidly screen millions of compounds and predict likely efficacy and safety profiles, but human medicinal chemists apply deep domain knowledge and intuition to interpret AI recommendations and design synthesis strategies. In manufacturing, AI-driven predictive maintenance systems can identify equipment anomalies before failures occur, but experienced operators and engineers make ultimate decisions about intervention timing and approaches. This collaborative model maximizes the unique strengths each partner brings while compensating for limitations, creating capabilities exceeding what either humans or AI could accomplish independently.

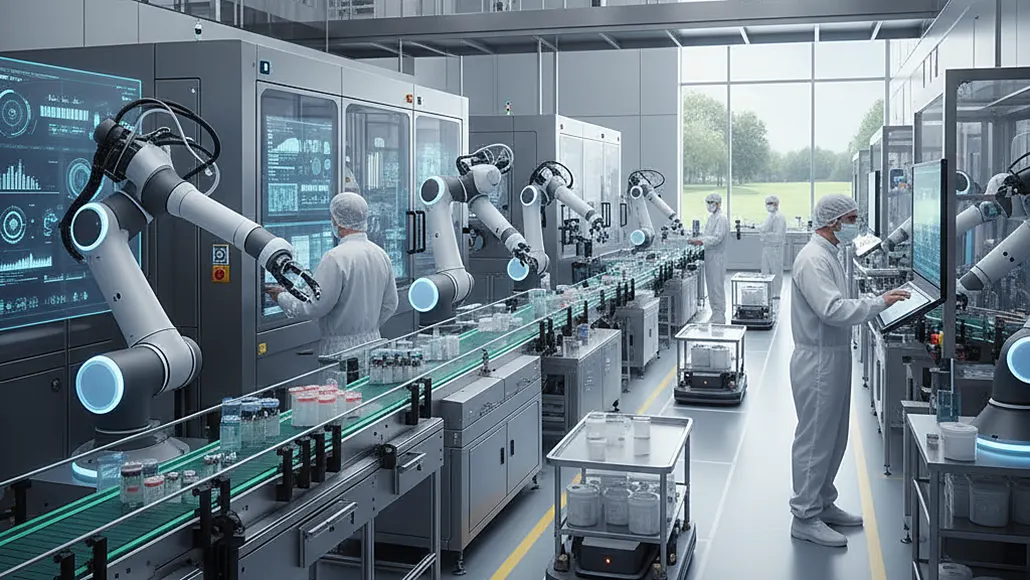

Advanced technologies including robotics, Internet of Things connectivity, digital twins, and blockchain create the infrastructure enabling Pharma 5.0 operations. Collaborative robots work safely alongside human operators in pharmaceutical manufacturing, handling repetitive or physically demanding tasks while humans focus on complex assembly, quality inspection, and problem-solving. Internet of Things sensors embedded throughout manufacturing facilities continuously monitor equipment performance, environmental conditions, and process parameters, feeding data to analytics systems that detect deviations and optimize operations. Digital twin representations of manufacturing processes enable virtual experimentation and scenario planning that de-risks changes to physical operations. Blockchain-based track-and-trace systems create immutable records of product provenance that combat counterfeiting while enabling efficient recall management.

Sustainability and resilience have emerged as explicit priorities within the Pharma 5.0 framework, reflecting growing recognition that pharmaceutical operations must minimize environmental impact while maintaining reliable medicine supply even during disruptions. Green chemistry principles guide development of manufacturing processes that reduce hazardous chemical usage, minimize waste generation, and improve energy efficiency. Circular economy concepts inform packaging design and material selection, favoring recyclable materials and reusable systems over single-use alternatives. Supply chain diversification and localized manufacturing reduce vulnerability to geographic concentrations and improve resilience against disruptions. The integration of sustainability considerations throughout pharmaceutical operations aligns with broader societal expectations while often generating operational efficiencies that improve business performance.

Transforming Drug Discovery and Development

The application of Pharma 5.0 principles to drug discovery creates possibilities for dramatically accelerating the identification and optimization of therapeutic candidates while improving success rates and reducing development costs. Generative AI models can design novel molecular structures optimized for multiple properties simultaneously including target binding affinity, selectivity, bioavailability, metabolic stability, and safety. These computational design capabilities expand the chemical space explored beyond what traditional medicinal chemistry approaches could access, potentially identifying breakthrough therapies that conventional methods would miss. However, the integration of AI-generated suggestions with human medicinal chemistry expertise ensures that computational predictions are validated experimentally and refined based on practical considerations including synthesis feasibility and formulation challenges.

Predictive modeling throughout preclinical and clinical development leverages machine learning algorithms trained on extensive datasets to forecast likely outcomes and identify optimal development strategies. Models predicting pharmacokinetic properties enable early optimization of drug-like characteristics, reducing attrition in later development stages. Clinical trial enrollment can be enhanced through AI-powered patient matching that identifies individuals most likely to demonstrate treatment responses, improving trial efficiency and success probability. Adaptive trial designs that modify based on accumulating data enable more efficient exploration of dose ranges and patient populations while maintaining statistical rigor. The combination of predictive capabilities with human judgment in trial design and interpretation creates more efficient development programs that bring effective therapies to patients faster.

Digital twins of biological systems from molecular through organ and whole-patient levels enable virtual testing of therapeutic hypotheses before committing to expensive physical experiments. Computational models of disease mechanisms can predict how interventions targeting specific pathways will affect disease progression, guiding target selection and validation. Virtual organs created from patient-specific data enable prediction of individual responses to candidate therapies, supporting personalized medicine approaches. These in silico capabilities complement rather than replace physical experimentation, enabling more strategic use of animal models and clinical trials by focusing on approaches with highest probability of success based on virtual predictions.

The integration of real-world evidence from electronic health records, insurance claims, and patient-generated health data creates continuous feedback loops that inform drug development and post-market surveillance. Analysis of treatment patterns and outcomes in clinical practice identifies patient populations where approved therapies demonstrate particular benefit or face challenges, informing life-cycle management strategies and potential label expansions. Post-market safety monitoring leveraging real-world data can detect adverse event signals earlier than traditional pharmacovigilance systems, enabling faster responses to emerging safety concerns. The convergence of development-stage evidence with real-world data creates comprehensive understanding of therapeutic value across diverse patient populations and practice settings.

Revolutionizing Pharmaceutical Manufacturing

Smart manufacturing represents perhaps the most visible manifestation of Pharma 5.0 principles, transforming pharmaceutical production from predominantly manual, batch-based processes to highly automated, continuously monitored operations characterized by real-time quality control and exceptional flexibility. The integration of robotics, process analytical technology, and advanced process control creates manufacturing systems that consistently produce high-quality products while adapting to changing demands and operating conditions. Continuous manufacturing systems that produce pharmaceutical products in uninterrupted flows offer substantial advantages over traditional batch processes including reduced production times, smaller equipment footprints, improved quality consistency, and enhanced flexibility to adjust production rates based on demand.

Process analytical technology deployed throughout manufacturing operations enables real-time monitoring of critical quality attributes and process parameters, creating opportunities for in-process adjustments that ensure final product quality rather than relying solely on end-of-batch testing. Near-infrared spectroscopy can assess blend uniformity during mixing operations, enabling optimization of mixing times to ensure content uniformity. Particle size analyzers monitor milling operations to achieve target particle size distributions that affect bioavailability. The integration of these analytical measurements with automated process controls creates closed-loop systems that automatically adjust process parameters to maintain product quality within specifications, reducing batch failures and improving manufacturing efficiency.

Digital manufacturing execution systems coordinate complex production workflows across multiple unit operations, equipment items, and facility areas while maintaining comprehensive documentation of all manufacturing activities. These systems assign work to operators and equipment, track material consumption and product flows, capture process data and quality measurements, and generate batch records documenting that products were manufactured according to approved procedures. The elimination of paper-based batch records reduces transcription errors, accelerates batch record review and release, and creates searchable digital archives that facilitate investigations and continuous improvement initiatives. Integration of manufacturing execution systems with enterprise resource planning, quality management, and supply chain planning systems creates end-to-end visibility and coordination across pharmaceutical operations.

Flexible manufacturing platforms capable of producing multiple products or dosage forms in shared facilities enable more efficient asset utilization while supporting personalized medicine approaches. Modular equipment designs and rapid changeover procedures allow switching between products with minimal downtime. Single-use technologies eliminate cleaning validation requirements between campaigns, further reducing changeover times and enabling economical production of smaller batches. The combination of flexibility with automation creates manufacturing systems that can efficiently produce everything from blockbuster drugs manufactured in millions of doses annually to ultra-rare disease treatments manufactured in hundreds or even dozens of patient-specific doses.

Enhancing Quality Management and Regulatory Compliance

Quality management systems evolve substantially under Pharma 5.0 paradigms, shifting from predominantly reactive approaches focused on detecting and correcting problems toward proactive, predictive systems that prevent quality issues before they occur. The integration of quality-by-design principles that build quality into product and process development with real-time monitoring and advanced analytics creates robust manufacturing operations that consistently deliver high-quality products. Risk-based approaches focus quality oversight on aspects with greatest potential to impact product quality or patient safety, enabling more efficient use of quality resources while maintaining rigorous standards.

Automated monitoring and deviation detection systems continuously analyze process data and quality measurements to identify unusual patterns that may indicate emerging quality issues. Machine learning models trained on historical manufacturing data recognize subtle signatures of process anomalies before they result in out-of-specification results or batch failures. Early warning systems alert quality and manufacturing personnel to investigate potential issues, enabling corrective actions that prevent quality problems rather than merely detecting them after they occur. The reduction in quality events and batch failures delivers substantial economic value while improving product supply reliability.

Electronic quality management systems automate many administrative aspects of quality operations including deviation investigations, change controls, and corrective and preventive action processes. Workflow automation ensures that quality events are routed to appropriate personnel for review and action, reducing response times and preventing oversights. Comprehensive audit trails document all quality system activities, supporting regulatory compliance while enabling analysis of quality trends and effectiveness of improvement initiatives. The integration of quality data across sites and systems provides enterprise-wide visibility into quality performance, enabling identification of systemic issues and sharing of best practices.

Regulatory compliance benefits from Pharma 5.0 technologies through enhanced documentation, improved data integrity, and more effective risk management. Automated data capture eliminates transcription errors and ensures contemporaneous recording of manufacturing activities. Electronic signature systems provide secure, traceable approval processes. Blockchain-based systems create tamper-evident records that assure regulatory inspectors of data integrity. The combination of these capabilities addresses regulatory concerns while reducing compliance burden on pharmaceutical companies.

Optimizing Supply Chain and Distribution

Supply chain management under Pharma 5.0 principles leverages advanced analytics, real-time visibility, and collaborative planning to create resilient, responsive networks that reliably deliver medicines to patients while minimizing costs and environmental impacts. Demand forecasting using machine learning algorithms that analyze historical sales patterns, market trends, and external factors enables more accurate predictions of future medicine needs. These improved forecasts support better inventory management, reducing stockouts and excess inventory while improving customer service.

Supply chain visibility platforms aggregate data from suppliers, manufacturers, logistics providers, and distributors to provide comprehensive real-time views of inventory positions and product flows. Advanced analytics identify potential disruptions before they impact product availability, enabling proactive responses. Network optimization algorithms suggest adjustments to manufacturing allocations, transportation routes, and inventory deployments that improve efficiency or resilience. The integration of supply chain data with enterprise planning systems enables coordinated decision-making across functions.

Cold chain logistics for temperature-sensitive biologics and cell therapies benefit substantially from Internet of Things sensors and connectivity that enable continuous monitoring of storage and transportation conditions. Real-time temperature data flows to cloud platforms where analytics systems detect deviations and alert logistics personnel to intervene before product quality is compromised. Data-driven route optimization balances transportation costs, delivery times, and product stability requirements to identify optimal shipping approaches. The combination of monitoring capabilities with predictive analytics improves product quality assurance while reducing waste from temperature excursions.

Last-mile delivery innovations including telepharmacy, home delivery services, and smart packaging create new possibilities for improving patient access and medication adherence. Digital health platforms connecting patients, pharmacies, and healthcare providers enable online prescription fulfillment and direct-to-patient shipping that removes geographic and logistical barriers to medication access. Smart packaging incorporating connectivity, sensors, and patient engagement features can remind patients to take medications, verify that doses are consumed as prescribed, and alert healthcare providers to adherence challenges. These patient-focused innovations align with Pharma 5.0’s human-centric philosophy by designing supply chains around patient needs rather than operational convenience.

Workforce Transformation and Human Capital Development

The shift toward Pharma 5.0 operations creates profound implications for pharmaceutical workforces, requiring new skill sets and potentially different organizational structures compared to traditional pharmaceutical operations. Rather than displacing workers, Pharma 5.0 automation typically shifts human effort toward higher-value activities including process optimization, data analysis, problem-solving, and continuous improvement initiatives. However, realizing these benefits requires substantial investment in workforce development to ensure personnel possess competencies needed in increasingly digital, data-driven operating environments.

Training and upskilling programs help existing pharmaceutical workers acquire digital literacy, data analysis capabilities, and familiarity with new technologies being deployed in Pharma 5.0 operations. Cross-training that exposes personnel to multiple aspects of pharmaceutical operations improves organizational flexibility while broadening individual career opportunities. Hands-on experience with new equipment and software systems, supplemented by classroom instruction and online learning resources, enables workers to effectively utilize Pharma 5.0 capabilities. Companies investing comprehensively in workforce development typically experience smoother technology implementations with better utilization of new capabilities compared to those treating training as an afterthought.

Organizational culture evolution proves critical for successful Pharma 5.0 transformations, as technological capabilities alone cannot deliver expected benefits without corresponding changes in how people work and make decisions. Cultures that embrace experimentation, tolerate intelligent failures, and reward continuous improvement create environments where Pharma 5.0 technologies thrive. Leadership must clearly articulate visions for how advanced technologies will enhance rather than threaten worker roles, addressing anxiety about automation while exciting teams about new possibilities. Recognition and celebration of early successes build momentum and demonstrate value, while transparent communication about challenges maintains trust during difficult transitions.

New roles emerge within Pharma 5.0 organizations including data scientists who develop and maintain analytical models, digital transformation leaders who coordinate technology implementations across functions, and change management specialists who support personnel through transitions. These roles require unique skill combinations spanning technical expertise, business understanding, and interpersonal capabilities. Pharmaceutical companies increasingly recruit talent from technology sectors while simultaneously developing internal candidates through rotational programs and leadership development initiatives. The ability to attract, develop, and retain people who can effectively bridge pharmaceutical domain expertise with digital capabilities becomes a key competitive differentiator.

Regional Opportunities and Strategic Positioning for the Middle East

The Middle East’s pharmaceutical industry has opportunities to leapfrog traditional development pathways by embracing Pharma 5.0 principles from the outset of capability building rather than incrementally transitioning from legacy systems. New manufacturing facilities can incorporate state-of-the-art automation, digital connectivity, and flexible production capabilities without constraints imposed by existing infrastructure and established practices. This greenfield advantage enables optimization of facility designs, process flows, and technology selections for Pharma 5.0 operations from inception.

Government support for pharmaceutical industry development throughout the Gulf region creates favorable conditions for Pharma 5.0 implementations through funding mechanisms, regulatory facilitation, and strategic planning that prioritizes advanced manufacturing capabilities. National visions emphasizing knowledge-based economic development align naturally with Pharma 5.0’s emphasis on high-value manufacturing leveraging advanced technologies and skilled workforces. The designation of pharmaceutical manufacturing zones with modern infrastructure and supportive business environments accelerates capability building while creating clusters where companies can share knowledge and resources.

Educational initiatives developing pharmaceutical and biotechnology talent with digital competencies position the region to supply skilled workers for Pharma 5.0 operations. Partnerships between universities, technical colleges, and pharmaceutical companies create educational programs aligned with industry needs. These programs emphasize not only pharmaceutical sciences but also data analytics, automation technologies, and quality systems that characterize Pharma 5.0 operations. International collaborations that bring experienced pharmaceutical professionals to the region for knowledge transfer accelerate capability development while creating mentorship opportunities for local talent.

The Middle East’s strategic position serving markets across Europe, Asia, and Africa creates opportunities for pharmaceutical manufacturing that balances localization benefits with export potential. Pharma 5.0 capabilities including flexible manufacturing, advanced quality systems, and efficient supply chains enable competitiveness in global markets while serving regional needs. As international pharmaceutical companies seek to diversify supply chains and reduce geographic concentration risks, Middle Eastern facilities implementing Pharma 5.0 capabilities could attract manufacturing partnerships and technology transfers that accelerate regional pharmaceutical development while contributing to global supply security.