Green Chemistry Driving Sustainable API and Ingredient Production

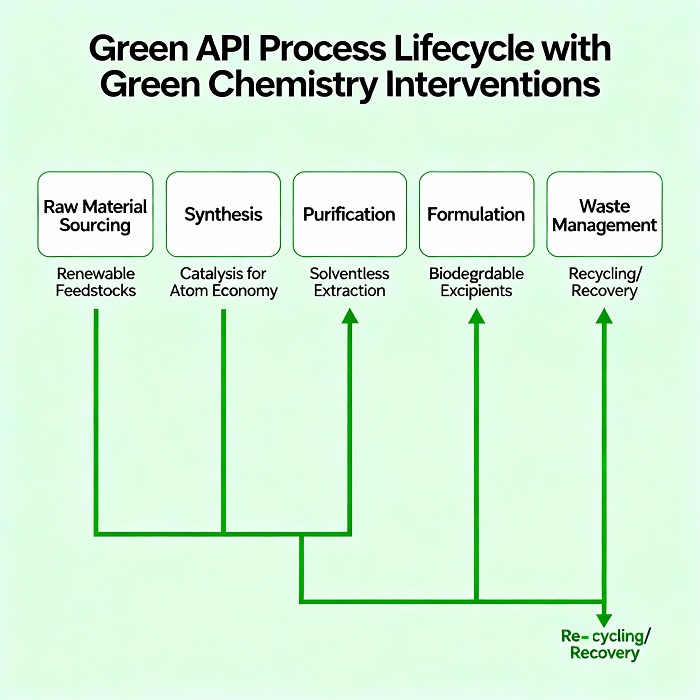

The pharmaceutical industry is at the cusp of a sustainability revolution, with green chemistry principles guiding the transformation of API manufacturing toward eco-friendly, resource-efficient processes. As environmental concerns mount, companies are increasingly adopting cleaner reaction pathways, renewable feedstocks, and waste-minimization strategies across the API supply chain.

Core Principles of Green Chemistry in Pharma

Core Principles of Green Chemistry in Pharma

At its heart, green chemistry emphasizes the reduction or elimination of hazardous substances in chemical processes. Key tenets include atom economy, solvent replacement, and energy efficiency, all of which have profound implications for API production standards.

Atom Economy and Waste Reduction

By designing reactions that maximize atom utilization, manufacturers minimize by-product generation. Catalytic processes, such as biocatalysis and photoredox catalysis, have gained traction for their high selectivity and low energy requirements, aligning with green chemistry in API manufacturing.

Solvent Innovation and Recycling

Solvent management represents a critical area of improvement. Many firms now employ benign solvents, such as water or bio-derived solvents, and implement closed-loop recycling systems. These innovations reduce volatile organic compound (VOC) emissions and lower operational costs by reclaiming valuable materials.

Case Studies: Pioneers in Sustainable API Production

Notable examples include major pharma players investing in continuous flow reactors and enzymatic syntheses. These technologies not only deliver high yields but also operate at ambient conditions, curbing energy consumption.

Continuous Flow Technology

Continuous manufacturing platforms enable precise control over reaction parameters and facilitate safer, high-throughput API synthesis. By integrating in-line analytics, companies achieve real-time quality assurance while minimizing resource utilization.

Conclusion

Embracing green chemistry in API manufacturing is no longer optional—it is an imperative for sustainable growth. Through innovations in reaction design, solvent management, and process intensification, the industry can reconcile environmental stewardship with robust pharmaceutical production.