Quality and Regulatory Trends Shaping API Manufacturing Standards

In today’s pharmaceutical landscape, stringent quality and regulatory requirements govern every aspect of API manufacturing. As authorities worldwide harmonize guidelines and enforce tougher inspections, manufacturers must adapt to evolving Good Manufacturing Practices (GMP) and compliance protocols.

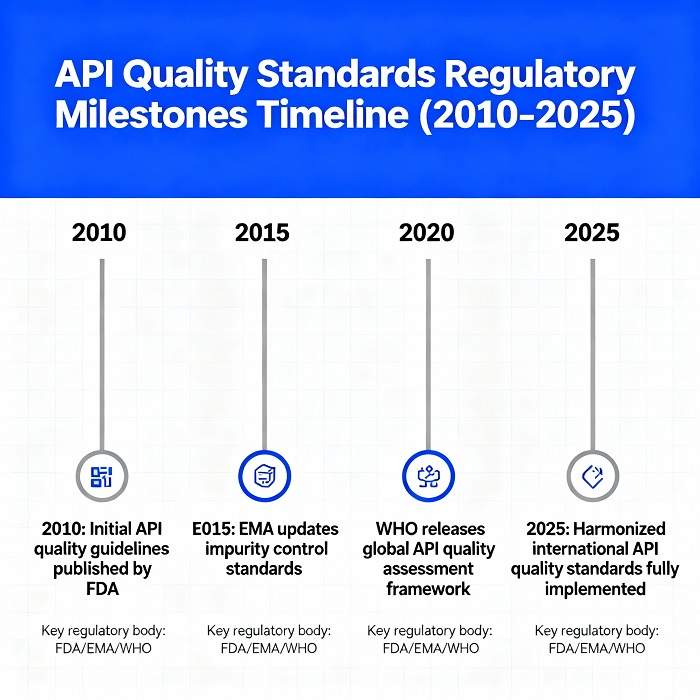

Harmonization of Global Regulatory Frameworks

Regulatory bodies including the FDA, EMA, and PMDA have intensified efforts to align GMP standards, facilitating smoother international trade and reducing duplication of inspections. This harmonization emphasizes risk-based approaches, data integrity, and robust quality management systems, ensuring that API manufacturing quality and regulatory trends remain globally consistent.

Risk-Based Quality Management

Modern GMP frameworks advocate risk-based Quality Management Systems (QMS) that prioritize high-impact processes. By implementing tools such as Failure Mode and Effects Analysis (FMEA) and Quality by Design (QbD), manufacturers can proactively identify and mitigate potential quality lapses within the API manufacturing workflow.

Enhanced Data Integrity Requirements

Authorities now mandate comprehensive data integrity measures, ensuring that electronic records and audit trails are accurate, complete, and secure. Manufacturers are deploying advanced IT solutions, including blockchain and secure cloud platforms, to maintain immutable records of batch production data.

Impact of Regulatory Pressures on Manufacturing Practices

Regulatory scrutiny has compelled manufacturers to invest heavily in facility upgrades, advanced process controls, and staff training. As part of compliance strategies, many companies are adopting real-time monitoring technologies, automated sampling systems, and predictive analytics to ensure continuous adherence to API manufacturing guidelines.

Regulatory Digitalization and Remote Inspections

The COVID-19 pandemic accelerated the adoption of remote inspections and digital tools by regulatory agencies. Virtual audits, enabled by secure video conferencing and cloud data access, have become integral to maintaining inspection schedules without physical site visits.

Future Outlook

Looking ahead, automation, artificial intelligence, and continuous manufacturing will further enhance quality consistency and regulatory compliance. As the API manufacturing quality and regulatory trends evolve, stakeholders must remain agile—embracing digital innovations and collaborative approaches with regulators to uphold high standards.